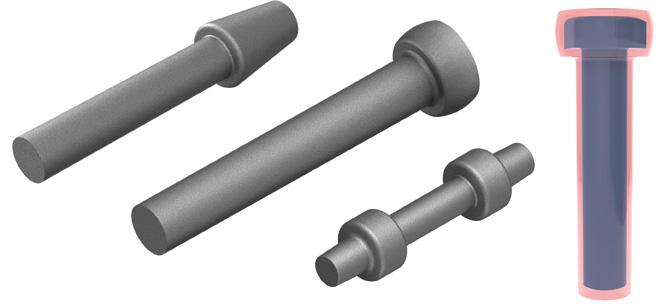

Brooks Forgings have increased production of upset forged blanks also known as uses at their manufacturing centre based in (Lye) Stourbridge, West Midlands.

By heating the bar and forging, the metal can be deformed to create a head, flange, or other shape at any position of the bar. In other words we move the metal to where it is needed

The Benefits to Machining & Fastener Companies:

Save up to 50% on material.

Improved machining cycle times.

Increase shop capacity as a result of reduced cycle times.

Better metal grain flow and strength.

Reduced material waste.

Reduced energy cost.

Reduced tool and tip cost, because of less material removal.

The Benefits to Drop Forging Companies:

Reduce pre-form operations and increased output.

Die cost and size reduced, by removing preforming impressions.

Less requirement to work away from centre-line of ram, reducing wear and stress on expensive components.

Reduced material waste.

Reduced energy cost, through reduced cycle times.

Please contact us today to discuss your requirements.