Considerable new investment has been made at our production facility based in Lye, Stourbridge to further improve KPI (Key Performance Indicator) targets.

Several data collection terminals are now located throughout the factory to enable our staff to log on and off jobs, allocate material stock and monitor production rates and volume at various stages.

The system gives us the ability to fully analyse jobs and calculate our true costs for the production and procurement of materials. From this, we can also calculate sold machine-hours and generate pre-emptive maintenance schedules. Production drawings and setup/manufacturing videos can also be accessed and viewed for each production job.

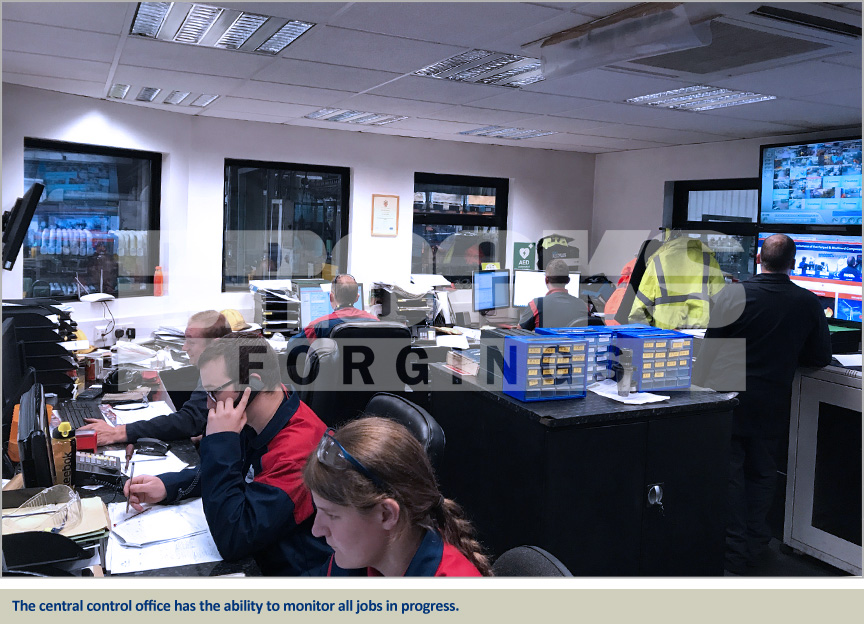

The central control office has the ability to monitor all jobs in progress and identify those that are behind schedule. As part of our on-going improvement scheme, the system is fundamental in improving overall production performance and helps us identify areas for improvement.